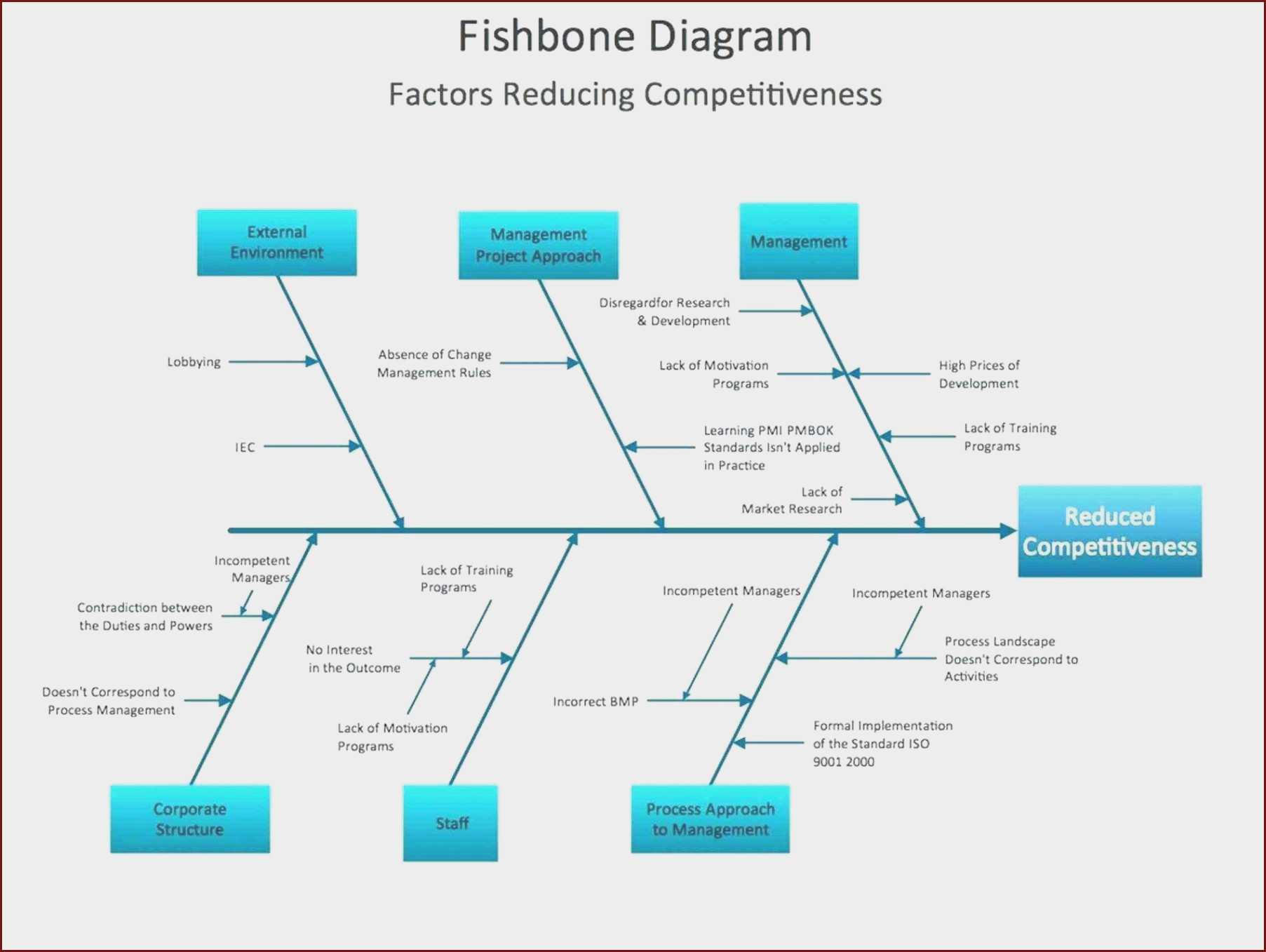

The end result should resemble a fish skeleton. Continue to add branches and a cause or effect until all factors have been documented. Details related to the cause or effect may be added as sub-categories branching off further from the main branch. These are usually one of the main categories discussed above. Write the description of the cause at the end of the branch. Causes are added with lines branching off from the main backbone at an angle. Write a brief description of the problem in the rectangle. Once the topic is identified, draw a straight, horizontal line (this is called the spine or backbone) on the page, and on the right side, draw a rectangle at the end. Discuss all possible causes and group them into categories. Define the process or issue to be examined. These are the best and most common practices when creating cause and effect diagrams. Is your distribution efficient and cost-effective? Is your product sold in the right stores or neighborhoods? Are your stores convenient for your target customers?īest Practices in Cause and Effect Analysis How is your product or service consumed? Is how or where you present your product hurting your ability to convert? Are your facilities clean and tidy? Is the packaging cheap or expensive? How does the price of your product or service compare to competitors? What discounts and payment methods are available? Consider advertising, sales, PR, branding, direct marketing, partnerships, and social media. How do you handle problems when they arise? Are they escalated properly? Is your staff trained appropriately and do they follow their training? Are there any potential problems with your company culture? When people buy your product or service they may interact with many people: sales people, customer service people, delivery people, and so on. Consider all aspects of what you're selling including its quality, its perceived image, availability, warranties, support and customer service.

In the marketing industry, cause and effect diagrams will often consist of 7Ps: Occasionally, a fifth category will be included called "Safety". Do you have too little of your workforce devoted to a process? Are new people adequately trained? Is the training consistent? Are the right people with the right experience being hired or promoted? Is there a specific position creating a bottleneck or making frequent mistakes? Is there too much moisture in the environment? Are temperatures too hot or too cold? Is there excessive dust or other contamination? Could there be errors in calculation or contamination that caused false readings? Could the way you measure be inconsistent in some way? Is your equipment regularly calibrated and maintained? Are there any issues getting raw materials from suppliers? Any problems with transportation (timing) or with the quality of the supplies? Are there any maintenance issues with the tools used or the number of tools available? Are there well-written and appropriate training guidelines in place? Are certain policies or regulations causing slow-downs or creating unnecessary steps? In the manufacturing industry, these are referred to as the 6Ms: Most cause and effect diagrams examine a similar set of possible causes for any issue analyzed.

0 kommentar(er)

0 kommentar(er)